Application

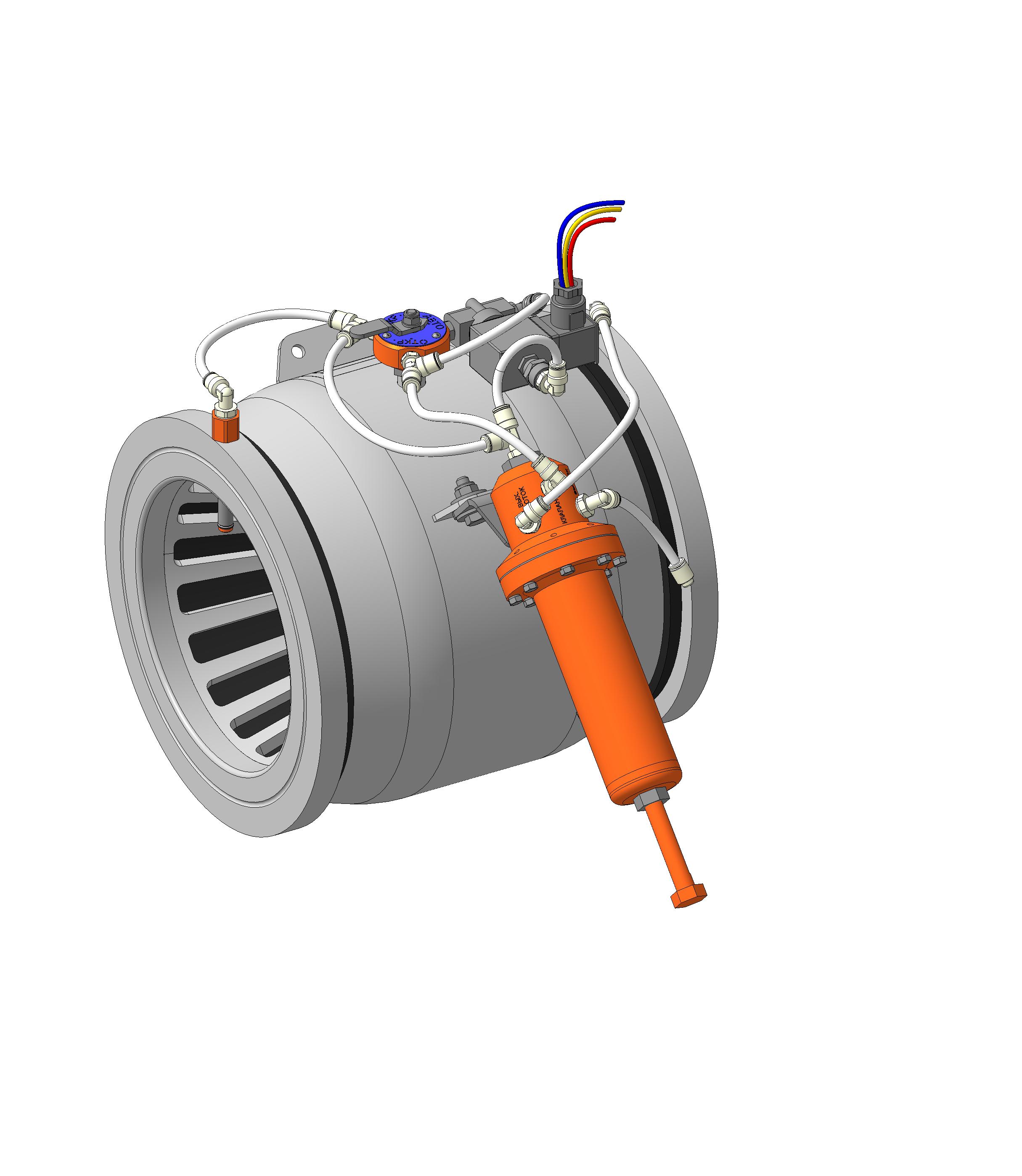

Designed to stabilize and reduce pressure in the water supply network, thereby protecting pipeline and equipment connected to it from high pressure.

Operating principle

|

|

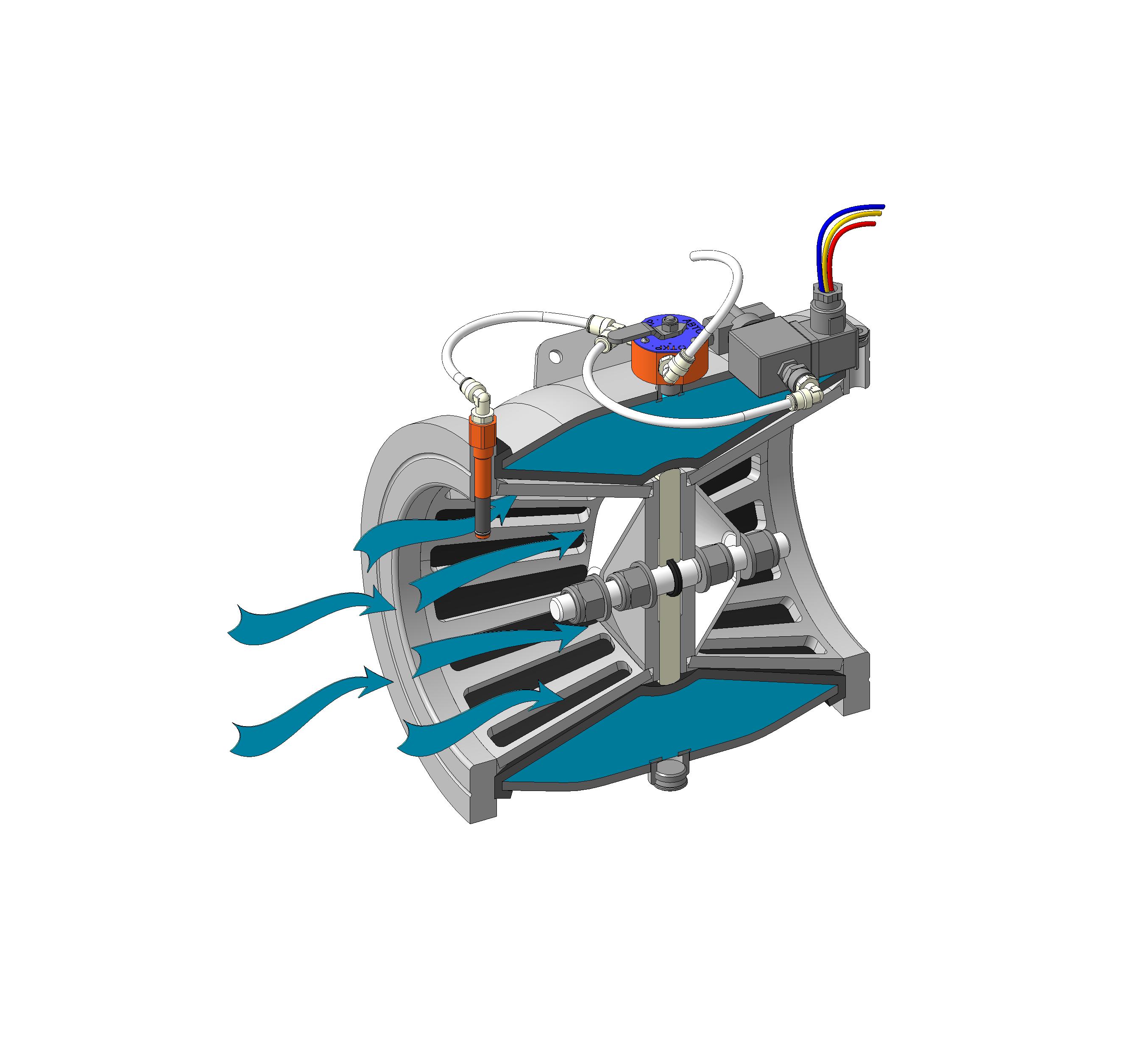

CLOSED upward flow of water presses on the outer chamber of the hose, brings the hose into hydraulic balance and closes the flow by pressing of the sleeve on the center saddle. |

|

|

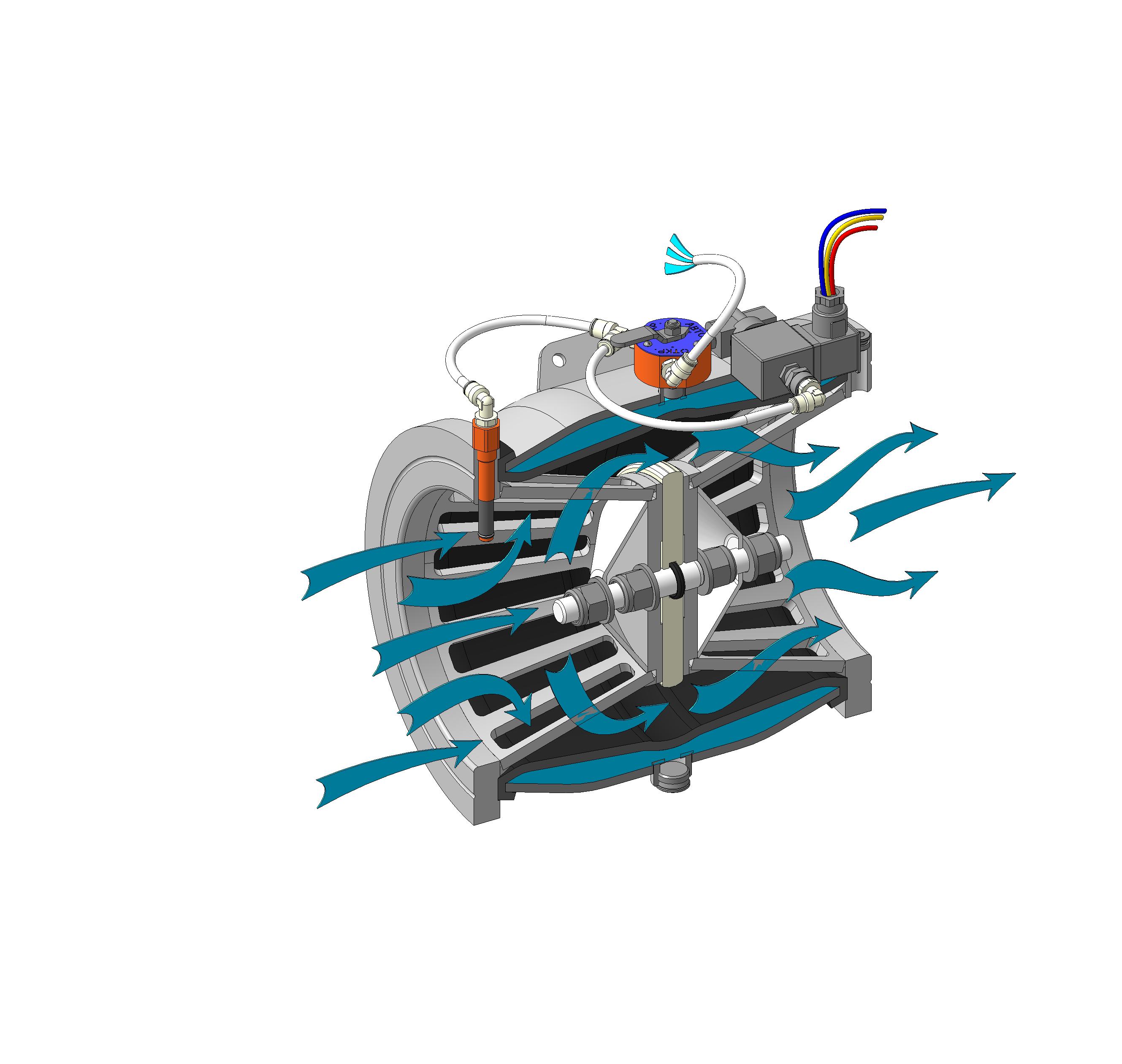

WHILE OPENED water pressure is released from the sleeve chamber, allowing the valve to open. |

|

|

VALVE FUNCTIONS

|

MANUAL CONTROL All valves are equipped with a three-way manual selector valve. Manual OPEN / CLOSE control is used to open or close. the valve. The flow through the valve is controlled by a rubber sleeve, which is driven by hydraulic pressure. The valve is positioned either in the full open or closed position. AUTO position on the selector does not affect valve control, but is used, when the valve is equipped with automatic control. |

|

AUTOMATIC CONTROL Additional solenoid for electrical control of the valve. If the valve is equipped with an electric solenoid, the OPEN / CLOSE function may be automatic using an electric controller. When the selector is in AUTO position, the electric solenoid is used to automatically open or close the valve. 3-way electric solenoid must be turned on to open the valve and de-energized to close the valve. Positioning of the manual selector to OPEN or CLOSE cancels the AUTO control. |

|

|

PRESSURE CONTROL VALVES The pressure regulator (which reduces it for the downward flow The pressure control valves react through the pressure regulator. The pressure regulator directs the water flow, which sets the clutch in operation. If the control function is to reduce the pressure, the position of the hose (or flow through the valve) is controlled by downstream pressure. If the control function maintains or relieves pressure, the position of the hose is controlled by the upstream pressure |

|